INTRODUCTION TO WELDING PROCESSES

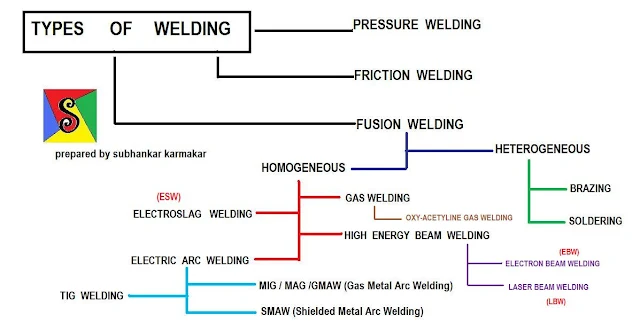

Modern welding technology started just before the end of the 19th century with the development of methods for generating high temperature in localized zones. Welding generally requires a heat source to produce a high temperature zone to melt the material, though it is possible to weld two metal pieces without much increase in temperature. There are different methods and standards adopted and there is still a continuous search for new and improved methods of welding. As the demand for welding new materials and larger thickness components increases, mere gas flame welding which was first known to the welding engineer is no longer satisfactory and improved methods such as Metal Inert Gas welding, Tungsten Inert Gas welding, electron and laser beam welding have been developed. In most welding procedures metal is melted to bridge the parts to be joined so that on solidification of the weld metal the parts become united. The common processes of this type are grouped as fusion welding. Heat must be supplied to cause the melting of the filler metal and the way in which this is achieved is the major point of distinction between the different processes. The method of protecting the hot metal from the attack by the atmosphere and the cleaning or fluxing away of contaminating surface films and oxides provide the second important distinguishing feature. For example, welding can be carried out under a shield comprising of a mixture of metal oxides and silicates which produce a glass-like flux, or the whole weld area may be swept clear of air by a stream of gas such as argon, helium or carbon dioxide which is harmless to the hot metals.

There are certain solid phase joining methods in which there is no melting of the electrodes, though heat is produced in the process. The melted and solidified cast metal is normally weaker than the wrought metal of the same composition. In the solid phase joining such melting does not occur and hence the method can produce joints of high quality. Metals which are dissimilar in nature can also be readily welded by this process. In the normal process joining of dissimilar metals will present problems because of the brittle intermetallic compounds formed during melting. Since the work pieces are closely pressed together, air is excluded during the joining process.

The welding processes those we shall discuss are gas welding, arc welding which includes manual metal arc welding (MMA), tungsten inert gas shielded arc welding (TIG), gas metal arc welding (MIG, MIG/CO2), submerged arc welding (SAW), etc. High energy density processes like electron beam welding, laser beam welding, plasma welding are also dealt with. Pressure welding and some special welding techniques like electro-slag welding etc. are also be discussed in detail.

Gas welding

- oxygen-acetylene welding

Fusion arc welding

- Shielded metal arc welding (SMAW)

- Submerged arc welding (SAW)

- Flux cored arc welding (FCAW)

- Gas shielded arc welding (MIG, TIG)

- MIG welding (gas metal arc welding)

- Pulsed MIG welding

- Hot wire MIG

- Plasma MIG

- TIG welding

- Pulsed TIG welding

- Hot wire TIG

- Spot TIG

Electrical method

- Electric resistance welding

(a) spot welding

(b) seam welding,

(c) projection welding,

(d) upset butt welding and

(e) flash butt welding

- Electro-slag welding (ESW)

- Induction pressure welding

Energy method

- Electron beam welding (EBW)

- Laser beam welding

- Plasma welding

Special methods

- Explosive welding (EW)

- Friction welding

- Diffusion bonding

Though the different processes have their own advantages and limitations and are required for special and specific applications, manual metal arc welding continues to enjoy the dominant position in terms of total weld metal deposited. The TIG process produces the finest quality weld on all weldable metals and alloys. The arc temperature may be upto 20,000 K. Although TIG welding produces the highest quality welds, it is a slow and expensive process. Metal inert gas welding process (MIG) is economical with consumable electrode fed at a predetermined rate.

Plasma arc welding (PAW) has made substantial progress in utilising the high heat energy of an ionised gas stream. The jet temperature can be as high as 50,000 K. Foils down to a thickness of 0.01 mm can also be welded in this process and hence this process is more useful in electronic and instrumentation applications.

All the processes like TIG, MIG and PAW can be successfully used for either Semi-automatic or automatic applications. But they are all open arc processes where radiation and comparatively poor metal recovery put a limit on using high currents. High productivity and good quality welds can be achieved by submerged arc welding process with weld flux and wire continuously fed. The slag provides the shielding of the weld pool with provision for addition of alloying elements whenever necessary.

Electron beam welding and laser welding are classified under high energy density processes.

For efficient welding the power source should provide controlled arc characteristic necessary for a particular job. In one case a forceful deeply penetrating arc may be required, while in another case, a soft less penetrating arc may be necessary to avoid ``burn through''. The welding process will also require a particular type of power source.

Table 1.1 gives the power source required for widely used welding process.